- Description

- Application

- Specification

- Warranty

- Measure

SeceuroDoor 95 Insulated Hi-Usage Industrial Roller Shutter – Three Phase 415V High-Speed Direct Drive Motor

Engineered for Intensive High-Frequency Industrial Operations

An insulated, hi-usage roller door, where daily usage is around 120 times per day (8 hour day) but with the caveat of a maximum of 30,000 'movements' as an overall rating. For higher ratings please speak to us as motor specification is critical above 120 operations per day.

A high quality, double skinned steel, industrial 'Traditional' build, hi-usage, insulated roller shutter door, using a three phase 415V, direct drive industrial GfA electric motor for operation. This is an excellent door package with the strength, security, wind resistance and insulation offered by the double skinned curtain as well as the higher rated motor drive. Consider this door for any medium to large openings with a busy and growing business.

High-Speed Performance for Maximum Operational Efficiency

The GfA high-speed direct drive motor configuration delivers significantly faster opening and closing cycles compared to standard industrial motors, dramatically reducing wait times and maximising throughput in busy loading bay environments. Where every second counts in fast-paced distribution centres, manufacturing facilities and logistics operations, the enhanced speed performance translates directly into improved operational efficiency, reduced vehicle queuing times and increased daily productivity across intensive shift patterns.

Engineered specifically for demanding high-frequency applications, this specification excels in environments where rapid door cycling is essential to maintain workflow efficiency. Busy warehouses processing frequent vehicle movements, manufacturing facilities with continuous production line access requirements, and distribution centres operating multi-shift patterns all benefit from the enhanced speed capabilities that minimise disruption and maintain operational momentum throughout extended working hours.

Premium GfA Industrial Motor Technology

GfA offer the very best industrial roller door motors, with leading edge technology and excellent, reliable, intelligent control options. The high-speed three-phase 415V direct drive motor system provides rapid, efficient operation specifically engineered for intensive daily use with frequent operation cycles. Unlike standard motors designed for moderate usage, this high-specification drive delivers consistent high-speed performance across 120+ daily cycles whilst maintaining exceptional reliability and longevity under continuous operational demands.

The advanced motor technology incorporates enhanced cooling systems, reinforced drive components and sophisticated control algorithms optimised for high-frequency cycling, ensuring dependable performance throughout extended operational periods without thermal stress or premature component wear typical of standard motors operating beyond their design parameters.

High-Usage Motor Benefits

- Usage Rating: Up to 120 operation cycles per 8-hour working day

- Maximum Lifetime Movements: 30,000 complete operation cycles

- Enhanced Operating Speed: Significantly faster than standard industrial motors for reduced wait times

- Continuous Duty Cycle Capability: Designed for multi-shift intensive operations

- Advanced Cooling Systems: Engineered for sustained high-frequency cycling without thermal stress

- Reinforced Drive Components: Heavy-duty specification for intensive industrial duty cycles

- Optimised Control Algorithms: Sophisticated programming for rapid, smooth operation

- Built-in Diagnostics: Fault diagnostics and maintenance cycle counters for service planning

Advanced Dual-Walled 95mm Insulated Profile Construction

The slat is 95mm high in profile and 20mm deep front to back with a foam injected core offering more strength and performance over any standard single skin slat. The slats are galvanised steel as standard for maximum protection against the intensive wear patterns associated with high-frequency operation.

The curved and ribbed lath design delivers exceptional strength, reduced deflection and enhanced security compared to standard single-skin profiles, crucial for doors subjected to intensive daily cycling where structural integrity and operational reliability are paramount. The robust construction withstands the mechanical stresses of continuous high-frequency operation whilst maintaining smooth, quiet performance throughout thousands of operation cycles.

Curtain Construction Benefits

- 95mm Profile Height: Enhanced strength and wind resistance for intensive operational demands

- 20mm Profile Depth: Deep insulated construction provides superior thermal and acoustic performance

- CFC-Free Foam Core: Fine-pored PU rigid foam infill delivers excellent insulation values

- Curved and Ribbed Design: Advanced profile geometry enhances strength whilst reducing deflection

- Reduced Operational Noise: Heavier profile sits tighter in guides, significantly reducing curtain rattle in high winds

- Enhanced Security: Robust dual-walled construction provides superior resistance to forced entry

- Damage Resistance: Twin-wall steel construction especially resistant to impact damage in busy operational environments

- Engineered for Intensive Use: Withstands mechanical stresses of continuous high-frequency operation

Superior Thermal and Acoustic Insulation Performance

Our Insulated Roller Doors combine all the qualities of the very robust SeceuroDoor 75 models but with the added benefit of insulation and also a quieter curtain in high winds because the slats sit tighter in the guides with more weight and deeper profile.

This insulated steel profile is especially resistant to damage and reduces deflection. With the option of interior and exterior identical colour coating our insulated shutter can easily be blended into the look of any building yet is also available with a galvanised finish.

Thermal and Acoustic Insulation

Minimal thermal bridges and the use of fine-pored PU rigid foam infill ensure good thermal insulation whilst curtain and sealing technology used around the entire shutter reduce noise from both inside and outside, maintaining stable working environments despite intensive operational patterns.

- Heat Transmission Centre: 1.1 W/m²K

- Heat Transmission Quirk: 3.2 W/m²K

- Minimal Thermal Bridges: Throughout door assembly for maximum energy efficiency

- Reduced Noise Transmission: Advanced curtain and sealing technology creates quieter working environments

- Significantly Quieter Operation: Compared to single-skin profiles with reduced curtain rattle

Outstanding Technical Specifications

- Lath Profile Height: 95mm nominal

- Lath Depth: 20mm (front to back)

- Lath Weight: 13.15 kg/m²

- Construction: Durable insulated galvanised steel with CFC-free polyurethane foam infill

- Core Material: Fine-pored PU rigid foam for maximum thermal and acoustic insulation

- Bottom Rail Height: 65mm with 23mm depth

- Maximum Width: 7000mm (7 metres)

- Maximum Height: 7000mm (7 metres)

- Maximum Area: 44m²

- Wind Class Rating: Class 5 (exceptional wind resistance for exposed locations)

- Guide Width: 80mm deep x 73mm wide (standard)

- Guide Arrangement Options: Choice of 4 guide configurations

- Standard Guide Angle: 100mm x 50mm

- Vision Option Available: 160mm x 58mm Clear Perspex Vision Panel with minimum 170mm spacing

- Motor Specification: High-speed three-phase 415V GfA direct drive motor optimised for intensive cycling

- Usage Rating: Up to 120 operation cycles per 8-hour day (maximum 30,000 lifetime movements)

- Enhanced Cooling Systems: For continuous high-frequency operation

- Reinforced Drive Components: Engineered for intensive industrial duty cycles

Comprehensive UK Regulatory Compliance

ALL SeceuroDoor products are:

- CE or UKCA Marked: Purchasing any product for commercial use requires full compliance with UK regulations. Approved LPCB products also available.

- ISO 9001 & ISO 14001 Certified: Manufactured within an ISO9001 and ISO14001 certified UK company

- Made to Measure as Standard: For a perfect fit

- Premium Quality Components: Using the highest quality components and electric motor drives

- Proudly UK Manufactured: At SWS dual production facilities in Lancaster and London

- Performance Tested: For long-term durability under intensive operational demands

Investment in Operational Excellence

The enhanced investment in high-speed, high-frequency motor technology delivers measurable operational benefits including dramatically reduced cycle times improving throughput efficiency, minimised vehicle wait times enhancing logistics performance, consistent high-speed operation throughout intensive shift patterns, exceptional reliability under continuous operational demands, reduced downtime costs through robust component specification, and enhanced productivity across busy facilities where door performance directly impacts operational profitability.

For facilities operating beyond 120 daily cycles or requiring specialised high-frequency specifications exceeding the 30,000 lifetime movement rating, please contact our technical team to discuss enhanced motor configurations and bespoke high-intensity operational solutions tailored to your specific industrial requirements.

Why Choose the SeceuroDoor 95 Hi-Usage with High-Speed Direct Drive Motor?

For UK industrial and commercial facilities requiring intensive high-frequency operation with rapid cycling capabilities, the SeceuroDoor 95 Hi-Usage represents the optimal solution. The advanced 95mm insulated profile delivers superior thermal and acoustic performance whilst the high-speed three-phase 415V GfA direct drive motor ensures consistent, reliable operation across 120+ daily cycles.

This specification is specifically engineered for demanding environments where every second counts—busy distribution centres, manufacturing facilities with continuous production requirements, and logistics operations where door performance directly impacts operational efficiency and profitability.

With made-to-measure manufacture as standard, comprehensive colour options, and full UK regulatory compliance, this door provides the ultimate solution for intensive industrial operations where high-speed performance, exceptional reliability and thermal efficiency are essential operational priorities.

Ideal for Intensive Industrial Applications

This is a great roller shutter door for so many applications and worth looking at over a single skin basic shutter as the extra cost is minimal compared to the benefits offered. The high-usage specification is particularly essential for:

- Busy distribution centres with continuous vehicle loading/unloading operations (60-120+ daily cycles)

- Manufacturing facilities requiring frequent production line access throughout multi-shift operations

- Logistics hubs with intensive goods-in/goods-out traffic during extended operational hours

- Warehouses processing high-volume order fulfilment with rapid door cycling requirements

- Industrial facilities operating 24-hour production schedules with continuous access demands

- High-traffic commercial premises where operational efficiency depends on minimised wait times

- Growing businesses anticipating increased operational intensity and expanded working patterns

- Facilities where downtime costs significantly impact operational profitability and productivity

Technical Specification – SeceuroDoor 95 Insulated Hi-Usage

Colours

This roller door is available with the curtain galvanised steel or prefinished in either a powdercoat finish which would be the same colour each side of the slat. All colours are supplied in a satin finish as standard. Matt and gloss are available, please email or call for price details. As totally standard and used by many people, depending on the roller door location, you can have the steel curtain in its natural galvanised steel finish.

We can offer the door in special colours other than the ones showing in our online shop options and of course you can mix and match the guides, hood cover and curtain if required, please email or call for details and prices.

High-Usage Motor Specification – GfA Three-Phase High-Speed Direct Drive

The high-speed direct drive 415V three-phase GfA industrial motor represents the ultimate in roller shutter automation technology, specifically engineered for intensive high-frequency industrial operations requiring rapid cycling and exceptional operational efficiency. This premium specification delivers significantly faster opening and closing speeds compared to standard industrial motors, dramatically reducing cycle times and maximising throughput in demanding operational environments.

High-Usage Rating and Performance Capabilities

- Usage Rating: Up to 120 operation cycles per 8-hour working day (higher operation cycle possible, please enquire

- Maximum Lifetime Movements: 30,000 complete operation cycles

- Enhanced Operating Speed: Significantly faster than standard industrial motors for reduced wait times

- Continuous Duty Cycle Capability: Designed for multi-shift intensive operations

- Advanced Cooling Systems: Engineered for sustained high-frequency cycling without thermal stress

- Reinforced Drive Components: Heavy-duty specification for intensive industrial duty cycles

- Optimised Control Algorithms: Sophisticated programming for rapid, smooth operation

High-Speed Direct Drive Motor Features

- Power Supply: Three-phase 415V industrial specification

- Drive Type: High-speed direct drive with integrated safety brake

- Motor Configuration: Patented Safedrive SI with built-in anti-fallback device

- Speed Performance: Enhanced rapid cycling optimised for high-frequency applications

- Operational Efficiency: Reduced cycle times maximising throughput and productivity

- Limits: Digital DES limits as standard for precision positioning

- Emergency Operation: Low-level hand chain operation as standard

- Mounting Options: Horizontal or vertical configurations

- Control Equipment: Plug-connected for easy installation and maintenance

- Certification: Certified to BS EN 12453 and BS EN 12604

- Diagnostics: Built-in fault diagnostics and maintenance cycle counters

- Design: Sealed maintenance-free units designed for intensive industrial use

When to Specify High-Usage Configuration

The high-usage specification is essential for facilities operating intensive operational patterns including busy distribution centres with continuous vehicle loading/unloading (60-120+ daily cycles), manufacturing facilities requiring frequent production line access throughout multi-shift operations, logistics hubs with intensive goods-in/goods-out traffic, warehouses processing high-volume order fulfilment, industrial facilities operating 24-hour production schedules, and growing businesses anticipating increased operational intensity.

For applications exceeding 120 daily cycles or requiring specifications beyond 30,000 lifetime movements, please contact our technical team to discuss enhanced motor configurations and bespoke high-intensity solutions.

Extended GfA Motor Warranty

An exclusive extended 2-year warranty is available on GfA industrial motors when you register each drive using the GfA bluetooth dongle. Registration provides comprehensive benefits including viewing and tracking all registered GfA assets, monitoring ongoing usage patterns, keeping track of drive settings over time, accessing a comprehensive library of fault codes for rapid diagnosis, and synchronising service records for fleet management.

Curtain Construction

The SeceuroDoor 95 features a high-performance dual-walled steel profile with high-density injected foam core construction. The curved and ribbed 95mm lath design delivers exceptional strength, reduced deflection and enhanced security, crucial for doors subjected to intensive daily cycling where structural integrity and operational reliability are paramount.

- Lath Profile Height: 95mm nominal

- Lath Depth: 20mm (front to back)

- Lath Weight: 13.15 kg/m²

- Construction: Durable insulated galvanised steel with CFC-free polyurethane foam infill

- Core Material: Fine-pored PU rigid foam for maximum thermal and acoustic insulation

- Bottom Rail Height: 65mm with 23mm depth

- Guide Width: 80mm deep x 73mm wide (standard)

- Enhanced Durability: Engineered to withstand intensive high-frequency operation cycles

Thermal Performance

Outstanding heat transmission performance ensures energy efficiency and environmental control across intensive industrial operations, maintaining stable working environments despite continuous operational patterns.

- Lath Heat Transmission Centre: 1.1 W/m²K

- Lath Heat Transmission Quirk: 3.2 W/m²K

- Minimal Thermal Bridges: Throughout door assembly

- Advanced Curtain and Sealing Technology: Reduces noise transmission

- Significantly Quieter Operation: Than single-skin profiles with reduced curtain rattle

Maximum Dimensions and Coverage

- Maximum Width: 7000mm (7 metres)

- Maximum Height: 7000mm (7 metres)

- Maximum Area: 44m²

- Wind Class Rating: Class 5 (exceptional wind resistance for exposed locations)

Guide Arrangement Options

Choice of four guide arrangement options to suit different installation requirements and building configurations:

- Face Fit: Outset angles (typical arrangement)

- Reveal Fit: Outset angles

- Inset/Outset: Mixed configuration

- Custom Arrangements: Available on request

- Standard Guide Angle: 100mm x 50mm

- Alternative Guide Sizes: Available to suit specific applications

Vision Panel Options

Optional clear perspex vision windows enhance natural light penetration and vehicle visibility, essential for safe high-frequency traffic management around busy loading bays.

- Vision Panel Dimensions: 160mm x 58mm clear perspex

- Minimum Spacing Between Panels: 170mm

- Configuration: Brickbond or in-line pattern

- Benefits: Increased natural illumination and improved safety for intensive vehicle movements

- Lath Weight with Vision: 13.15 kg/m² (identical to solid lath)

Powder Coating Options

- Colour Range: Available in any RAL or BS colour to match corporate branding or building facades

- Coating Thickness: 60-80 micron

- Standard Finish: SeceuroDoor 95 supplied in matt finish as standard (gloss level 30 ±5)

- Satin Finish Available: Gloss level 65 ±5

- High Performance Finish: Delivering exceptional corrosion protection and durability

- In-House Facilities: Powder coating facilities in Lancaster and London ensure rapid lead times

Plastisol Coating Options

- Coating Thickness: 200 micron PVC protective coating in leathergrain embossed finish

- Application: Applied to external face of curtain (solid laths only)

- Available Colours: White, Black, Goosewing Grey, Merlin Grey, Anthracite Grey, Ocean Blue, Slate Blue, Sargasso Blue, Moorland Green, Olive Green, Juniper Green, Mushroom, Vandyke Brown, Poppy Red, Aztec Yellow, Solent Blue

- Exceptional Corrosion Resistance: And impact resistance

- Suitable for Harsh Environments: And intensive operational use

Controls

The electric high-speed direct drive 415V motor can be controlled by various methods optimised for intensive operational environments:

The most basic method is an internal wall mounted push button station with a hold to run logic. You stand and hold the button firm for the duration of the opening or closing cycle and this way no safety edge or beam systems are legally required keeping the costs to a minimum. Of course you must be able to enter the building via another door for this method.

The second option is a wall mounted GfA TS control panel which can be programmed to have an impulse operation meaning you simply push the up or down button momentarily and the door will auto operate and has safety edge detection built in with the bottom T rail section to stop if an obstacle is met. The GfA TS panel includes maintenance cycle counters essential for tracking intensive usage patterns.

Other access controls are available from auto opening by radar or magnetic loop to digital keypads or key switches and even smart controls linked to other systems, ideal for optimising workflow efficiency in intensive operational environments.

Call or email for details and prices.

Advanced Safety Accessories for High-Traffic Environments

For enhanced safety in intensive high-frequency operational environments, a comprehensive range of BEA safety accessories is available including laser safety systems (LZR-I100/I110 and LZR-Widescan), motion detection and presence sensors (Condor), loop detectors for automatic vehicle detection, and red/green LED traffic lights for safe vehicle and pedestrian flow management in busy loading bay areas with frequent door cycling.

Manufacturing and Compliance

- UK Manufactured: Proudly manufactured in the UK at SWS dual production facilities (Lancaster and London)

- CE or UKCA Marked: Ensuring 100% compliance with UK building regulations

- ISO9001 Quality Certified: Manufacture

- ISO14001 Environmental Certification

- Made-to-Measure as Standard: For perfect fit

- Universal Laser-Cut Folded End Plates: For enhanced strength

- Pre-Slotted Angles: For easy on-site adjustments

- Pre-Drilled Guide Channels: With low-profile bolts

- Deburred Door Edges: For safer, easier fitting

- Performance Tested: For intensive high-frequency operational demands

Performance Benefits Summary

- Dramatically Reduced Cycle Times: Improving throughput efficiency

- Minimised Vehicle Wait Times: Enhancing logistics performance

- Consistent High-Speed Operation: Throughout intensive shift patterns

- Exceptional Reliability: Under continuous operational demands

- Enhanced Thermal Insulation: Reducing heating costs despite frequent door cycling

- Superior Acoustic Performance: Creating quieter working environments

- Reduced Downtime Costs: Through robust high-specification components

- Enhanced Productivity: Where door performance directly impacts profitability

SeceuroDoor Product Warranty

All SeceuroDoor products, including the industrial motor, are guaranteed against defects of material or workmanship by SWS UK, subject to correct installation, maintenance and operation, for a period of 1 year from the date of purchase. This comprehensive warranty provides peace of mind and protection for your investment in premium industrial door solutions.

Extended Warranty for GfA Motors

An exclusive extended 2-year warranty is available on GfA industrial motors when you register each drive using the GfA bluetooth dongle. Registration is straightforward and provides additional benefits including viewing and tracking all registered GfA assets in one place, monitoring ongoing usage patterns, keeping track of drive settings over time, accessing a comprehensive library of fault codes, and synching your service records.

Warranty Coverage

SWS UK will replace or repair any components of our products where the manufacturing process has resulted in a defect occurring during the relevant warranty period, subject to the exceptions and conditions detailed below. For all replacement electrical parts, the warranty period is 12 months or the remainder of the original warranty period, whichever is the longest.

Warranty Limitations and Exclusions

The SeceuroDoor warranty does not cover the following circumstances:

Visual Quality Standards

- Marks, distortion, stains, blemishes, indentations or scuffs which are not observable from at least 3 metres away in natural light (not direct sunlight)

- Minor variations in finish associated with the manufacturing process

- Impact damage or scratches, dents, scuffs or other minor abrasions occurring post-installation

Installation and Maintenance Issues

- Incorrect installation of the product, not following SWS UK's installation instructions

- Incorrect operation of the product or lack of proper care and maintenance in accordance with SWS UK's Operating & Maintenance Manual

- Any modifications made to the product by anyone other than SWS UK

- Use or attempted use of non-SWS UK spare parts

- Repairs or attempted repairs undertaken by any person other than someone specifically authorised by SWS UK

- Any attempt to reduce operating clearances by means of infills or draughtproofing

Normal Wear and Environmental Factors

- Normal wear and tear from regular usage

- Accidental or malicious damage from third parties

- External influences such as extreme or abnormal weather conditions, fire, water, salts, chemicals and bird droppings

- Any fault or surge in the customer's electricity supply

- Any failure of masonry or other structures onto which the product has been fixed

Coastal and High-Corrosion Environments

- Rust or corrosion caused by exposure to saltwater or salty air for products installed within 500 metres of the sea or a large body of saltwater

- For products installed within 2 miles of the sea, the exterior finish of the product is guaranteed for a limited period of 2 years only (regular weekly cleaning with warm water and mild detergent is essential)

Consumables and Consequential Costs

- Consumable items such as fuses, light bulbs or batteries

- Indirect, special or consequential loss or damage howsoever caused, including remedial work costs, call-out fees, tool or plant hire and transport costs

Important Warranty Conditions

The SeceuroDoor warranty covers parts only and does not cover labour costs or consequential costs. This includes but is not limited to call-out fees, transport costs and costs for remedial work for removing and/or re-installing faulty parts. All warranty claims must be reported promptly to allow for timely assessment and resolution.

Product Care Requirements

To maintain warranty validity and prolong the life of your SeceuroDoor product, correct operation and care in accordance with the official Operating & Maintenance Manual is essential. Regular maintenance includes wiping with a damp cloth and mild detergent to remove excessive dirt and grime, ensuring the floor is kept smooth, level and clear of dirt and debris which can damage the rubber seal, and conducting visual inspections to identify any issues before they develop into major problems.

Coastal Installation Requirements

Products installed in coastal environments or high-corrosion areas require enhanced maintenance protocols. Regular cleaning of products in locations within 2 miles of the sea is especially important. Doors should be cleaned thoroughly weekly using warm water and mild detergent with a soft cloth or sponge, allowed to dry naturally. Never use strong detergent, abrasive, caustic or solvent-based cleaners as these will void the warranty.

Visual Quality Assessment Standards

We recommend performing a visual quality check on installation. Carry out the quality check in natural daylight, not direct sunlight. Stand at a distance of 3 metres from the product to view the overall appearance. The product is acceptable if, taking into account the manufacturing process, none of the following is readily visible on the face of the product: marks or distortions associated with the manufacturing process, minor indentations, marks or scuffs on the surface, or paint or stain blemishes.

Making a Warranty Claim

For warranty claims or technical support, please contact Samson Doors on 01933 448 850 or email enquiries@samsondoors.co.uk. Please have your order details, installation date, and a clear description of the issue available. Our technical team will assess the claim and arrange appropriate resolution in accordance with the warranty terms.

Protecting Your Investment

Regular professional servicing and maintenance by qualified engineers will help ensure optimal performance and longevity of your SeceuroDoor product. Samson Doors offers comprehensive maintenance contracts and emergency repair services across the UK to keep your industrial doors operating reliably year after year.

Measuring Guide for SeceuroDoor 75 Traditional (Industrial Motor)

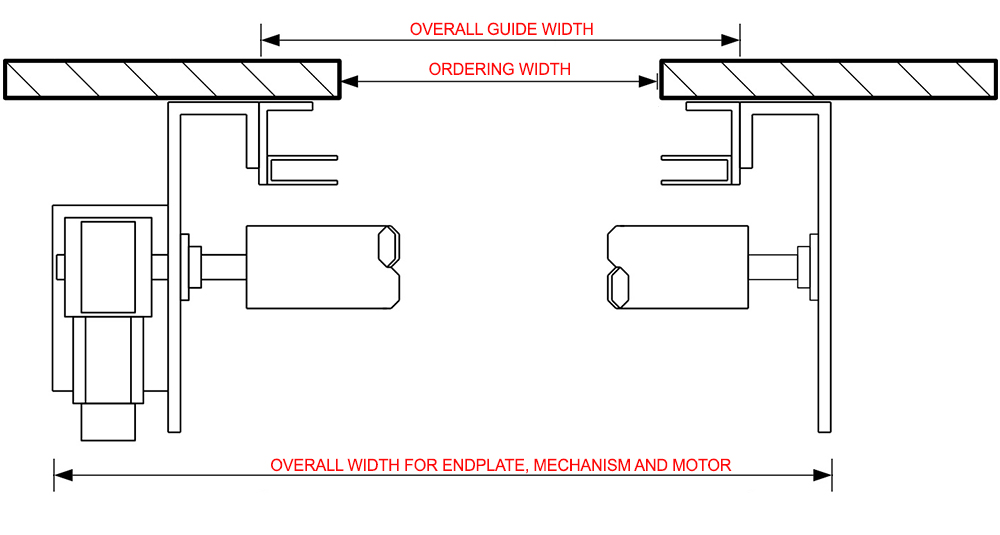

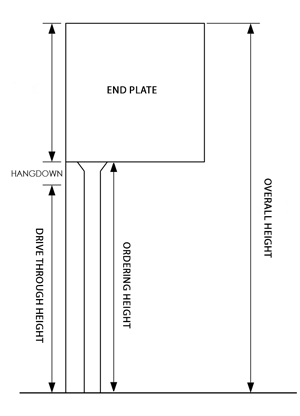

Understanding Ordering Dimensions

The measuring, pricing and ordering dimensions for any electric roller shutter door with an industrial electric motor drive are based on the OPENING WIDTH and GUIDE HEIGHT, excluding the guides for the width and endplates for the height. This measurement principle applies regardless of whether it is a single phase or three phase electric motor system.

Key Measurement Rules:

- OPENING WIDTH (between guides) = Ordering Width

- GUIDE HEIGHT (endplates excluded) = Ordering Height

See measuring diagram below for visual reference.

Traditional Build Installation Considerations

The Traditional build roller shutter door uses heavy-duty steel guides and steel angle profiles for installation, which can all be specified to suit different installation requirements and fixing configurations. This flexibility makes the Traditional build ideal for challenging or non-standard openings.

Overall Width at Endplate Level

The overall width at high level where the endplates are fitted will be wider than the overall guide width, and can be wider still depending on the choice of inboard or outboard motor setup.

The electric motor side with an outboard motor configuration requires more side room than the non-motor side at endplate level. Chain drive or direct drive motor choice will also vary the width required for the motor assembly.

Manual Override Access

The emergency manual override included as standard is positioned on the same side as the motor internally and is accessed directly underneath the endplate. Other positions may be available on request to suit specific site conditions.

Endplate Size Variations

The endplate size will vary depending on the door model and height, and therefore the size of the curtain roll when fully opened and rolled up. Please be aware to check the drive-through height and endplate dimensions if your headroom is critical.

Installation Methods

Face Fit - Behind the Opening (Recommended for Traditional Build Industrial Doors)

Most industrial roller shutter doors are installed to the inside face of the aperture. In a perfect scenario, your daylight opening dimensions are the space between the guides and underneath the endplate dimensions. However, it is important to note that any roller shutter will always have a 'hang down' when opened fully, making the final drive-through height slightly less than the height of the guides.

This hang down is normal and varies on different models depending on the curtain specification and roll diameter. If your opening drive-through height is critical, please speak to us first to determine the best height to order for your specific application.

Reveal Fit - Between the Opening

Some roller shutter doors are installed between the aperture opening (reveal fit), and this is where the electric tube motor roller door arrangement works particularly well, as all components are positioned inboard from the ordering dimensions.

You can install any roller shutter door between an opening, but please note that industrial motor-driven models require some additional steelwork or sub-framing to make them fit between the reveal properly and securely. The Traditional build's adaptable steel guide and angle system makes this easier to achieve than with fixed Continental-style arrangements.

Traditional Build Industrial Motor Driven Arrangement and Ordering Dimensions

(showing outboard direct drive motor arrangement)