Manual Roller Shutter Doors

Manually operated, industrial specification, roller doors, are usually installed in applications where the usage is very low, such as a farm building, or private storage warehouse where the door is perhaps only opened once or twice a week. Of course, if there is no electricity available the choice is already made for you.

Manual push up operation

Up to a certain size and curtain weight a roller door can be spring assisted and with a lock in the bottom section of the curtain. Spring assisted roller doors are balanced by a spring in the barrel on which the door curtain rolls around and this spring is tensioned to adjust depending on the curtain weight and to a certain extent the height. The spring assisted manual shutter is not the best option for an industrial door and will be awful to use during the winter months, bending down in the rain, wind and snow to operate the locking and grab the handle.

The centrally position lock in the bottom T rail will throw 2 rods outwards when locking and with this kind of lock the shutter can be locked from either side as required.

Locks can be fitted into the side guides too, but this is normally for shopfront security shutters.

Safety

Any spring assisted shutter used over a doorway, or any opening which a human may pass underneath must have a fail safe system fitted for CE approval. This is normally a secondary spring to ensure if the main spring, or any related component breaks for any reason, the second spring will ensure the shutter does not drop like a guillotine.

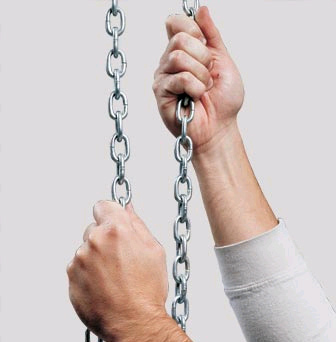

Chain Operation

The normal manual operating mechanism for an industrial roller door is a steel chain pulley system with gearing at high level to suit and provide an easy operation. There is no way the opening or closing speed can ever be particularly fast with a manual chain system as the gearing takes the speed right down as a compromise for effortless operation. As the speed is so slow the manual operation is only really suitable, as we said, for low usage doors.

The normal manual operating mechanism for an industrial roller door is a steel chain pulley system with gearing at high level to suit and provide an easy operation. There is no way the opening or closing speed can ever be particularly fast with a manual chain system as the gearing takes the speed right down as a compromise for effortless operation. As the speed is so slow the manual operation is only really suitable, as we said, for low usage doors.

Locking and security for a chain operated roller door is by a steel keep fitted as about chest height. The chain is secured into the keep and often padlocked, although the chain is nearly always situated inside the building, except for very occasional installations where the door is the last and first point of access, or the door is installed externally for some reason.

Further locks can be added - the ‘bullet’ locks in the guides which effectively pushes a steel rod through a drilled hole in the curtain either side at around chest height again. These bullet locks are secured into their housing by a small pin which is released by turning a key in the barrel of the lock body. With a bullet lock either side, and the cleat, the door is reasonably secure, but for even further security a steel ‘hasp and staple’ type mechanism can be welded to the bottom rail, or a simple steel section which is secured to the ground with a heavy duty padlock. This way anybody wanting to break in will require some fairly robust cutting tools as the bottom slat is the strongest in the curtain of the roller door.

Summary

Summary

Although many people we talk to every day say they are looking for a manual and basic steel roller shutter so many of them end up buying an electric operated roller door as it is not realised how small the difference can actually be in price. In fact, at certain sizes it may actually be cheaper to have a singe phase tubular motor drive and certainly far more convenient when operating the shutter, infrequently or not.

A manually operated roller shutter is fine as long as the operational effort is understood fully and the speed at which a large door will open and close is also taken into account.