- Description

- Application

- Specification

- Installation

- Measure

Elegant & Award Winning

An award-winning, semi-cassette retractable awning, the Markilux 1600 offers excellent quality and elegance.

The manual version of the 1600 allows for simple operation where shading is desired for your patio and outdoor living area.

The aesthetic and design of the 1600 has led to it being awarded with the IF product design award, one of the most prestigious available over the world, and a true credit to the excellent craftmanship used to manufacture this awning.

Markilux 1600 Details

As a semi cassette awning, the underneath is open, however it still appears almost fully covered when closed. The top cover profile adapts itself to the angle of the awning pitch and closes completely flush with the front profile when retracted. The cover is completely protected from rain and snow.

The Markilux 1600 awning has a round 50mm torque bar, offering excellent resistance to any twisting and deflection. The Awning has a double steel-link chain system in the arms with an optional 'bionic tendon' system.

The coverboard is fitted with a brush which removes most of the dirt and debris as the awning is being retracted. The coverboard adapts itself to the pitch of the awning automatically thanks to a unique and patended mechanism, meaining that there is no gap between the coverboard and the front profile.

Various options are available that allow you to enhance the 1600 and truly make it your own. These features include LED lighting, increasing your comfort and creating a desirable ambience, whilst the ShadePlus, sunlight sensors and virabox are also available.

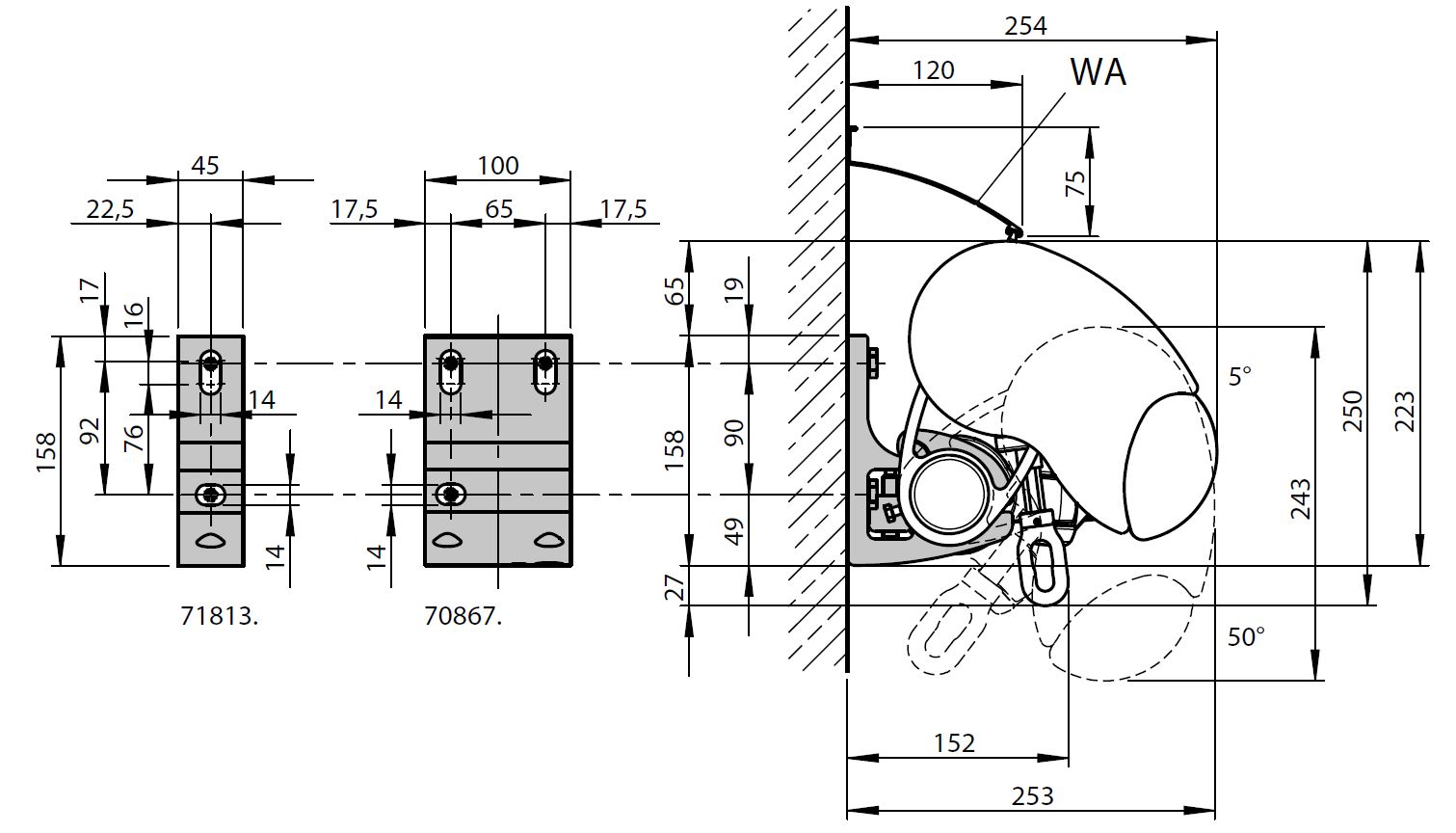

Dimensions

The roller tube is 85mm in diameter.

Maximum Width: 7100mm

Maximum Projection: 4000mm

Suitable for Balcony and Patio Areas.

Face Fixing Installation - Other fitting positions are available. Contact Us for more information

Click here to view the Markilux 1600 Awning Brochure, PDF >

Dimensions: Max. 7100mm wide x 4000mm projection

Folding arm using a twin chain system or optional bionic tendon

Options:

LED spotlights (electric version only)

End caps in polished chrome

ShadePlus valance

Coupled units larger than 7100mm wide

Stretch version when a projection greater than the width is required

The cassette can be powdercoated in the following colours:

Traffic White - RAL 9016

Metallic Aluminium RAL 9006

Anthracite Metallic 5204

Stone Grey Metallic 5215

Off White Textured Finish 5233

Grey Brown (similar to RAL 8019)**

Light Ivory RAL 1015**

Havana Brown Textured Finish 5229**

**extended lead-times may apply

Operation:

The Markilux 1600 Awning is manually operated by the means of a stainless steel winding handle. The eyelet for the winding handle can be specified either side of the awning when ordering.

Installation Instructions available on request.

Any of the Markilux awnings require at least 2 people for installation. They are a very heavy single item to lift and the fixings for the brackets must be appropriate for the type of structure they are being fixed to. Although it is possible to install these yourself it is advised to engage the services of a professional installer. The bracket position is also fairly critical for a safe installation and most awnings will have a fixed position for the brackets depending on the model and size.

When measuring for any awning we advise you do try to get as large as possible for maximum sun protection. All Markilux awnings have an adjustable main fabric cover for the angle of the cover. The projection can be stopped at any point between closed and maximum projection depending how much shade is required.

The dimensions for ordering are the OVERALL width of the cassette and the fabric will always be smaller depending on the awning model. The projection is the maximum distance when fully extended for the awning cover and front profile.

The brackets for installation will vary in their positions depending on the awning model and the width required.

2 brackets are the minimum, with up to 8 required on very large awnings.

The position is critical and the brackets are usually directly behind the position of the arms with some tolerance on many models.

Please make sure the intended stucture for installation is suitable and if there are any doubts then speak to us about spreader brackets to spread the loads onto more stable sections if possible.