Measuring, specifying and ordering a Hormann sectional garage door

First Considerations

The sectional garage door is a door type that opens and closes vertically and curves around profiled steel tracking in seperate sections to then end up following the line of the ceiling horizontally.

It offers excellent unique properties compared to most other garage doors and was designed primarily for installation BEHIND the garage structural opening, but developments over the years now mean it can easily be installed INBETWEEN the structural opening if required.

As installing a sectional garage door behind the garage opening gives you a wider and higher drive through space and also optimises the insulation properties from the door panels, this is normally the position preferred, it is also easier to install this way.

Sectional Door Sizes

The Hormann range of sectional doors are ordered in sizes which relate to the actual frame opening size inside the steel fixing frame system.

The doors are ordered either in metric or imperial sizes but be aware with the imperial sizes they can be the nearest rounded up size. i.e a 7 foot high door is actually 2125mm which is 9mm shorter than 7'. You are better to work in metric dimensions for the sake of getting it perfect.

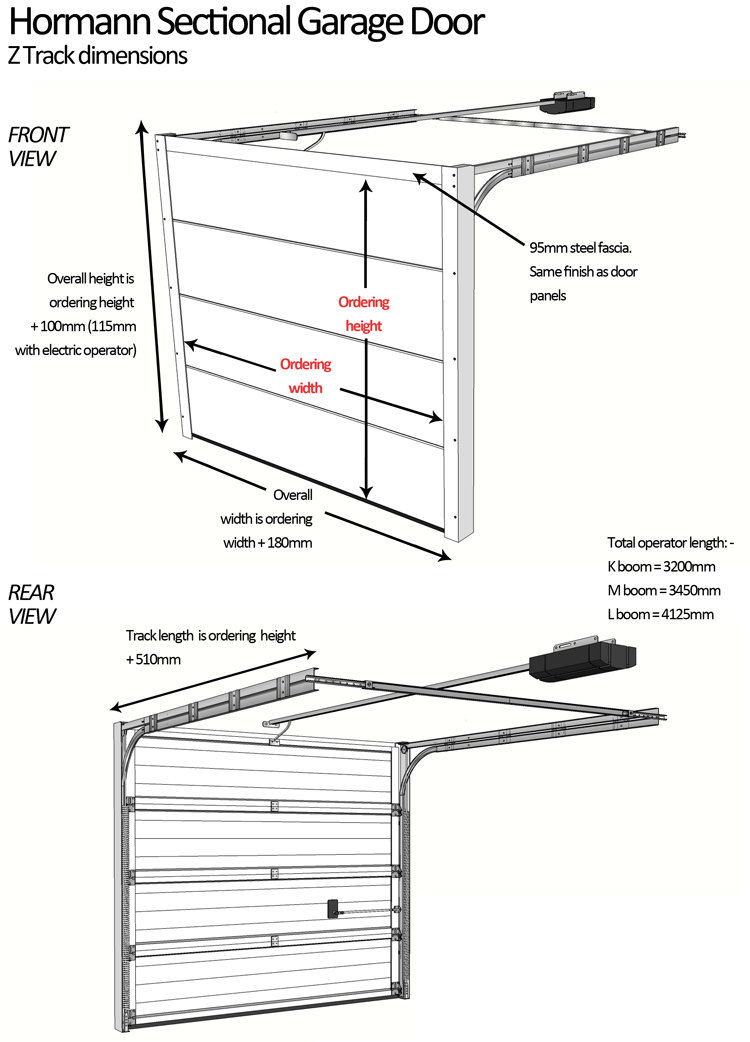

Below, the diagram shows the size references, but this diagram only refers to the Z track gearing, please be aware of the differences when you order the N or L track versions if required. The basic difference is you may need more headroom for the N track and the L track gear will come into the garage further. See the diagrams lower down on this page.

Any of the sectional door sizes have a constant dimension width for the vertical frame sections (the ‘legs’) but give 3 different measurement requirements for the standard headroom requirements which is determined by the type of springing and gearing system ordered.

When ordering a Hormann sectional garage door the size ordered will always have the steel frame surround and spring system to add to the order size which when installing behind a structural opening is usually an easy calculation if there is sufficient side room internally and head room above the lintel.

The 3 standard different springing positions that determine the headroom required are shown below:

|

|

|

|

For any of the above measurements you have to add 25mm for the standard boom type electric operators if required.

Installation Position

Where is the best place to install the sectional door you may ask, but in most cases this position is already determined by the width, depth, and height of the garage opening itself. You would always install behind if possible, as it is the easiest and gives maximum width and height, but if your piers are deep or headroom restricted you may have to install inbetween. An inbetween installation is not unusual but it needs some thought to make the sectional door and sub frame as easy as possible to finish off and give you a useable drive through size when open. Always bear in mind with a sectional door that the horizontal door tracks do come into the garage a lot further than a normal up and over door tracking will. The general rule of thumb is to add about 500mm to the door ordering height, but this can vary, so always check if in doubt about internal obstructions such as secondary piers or lintels, etc.

When installing inbetween also remember the insulation values can be seriously comprimised as the side and head frame is only single skin steel construction.

Insulation panel add ons are available to ensure the best insulated values, but it is still better to get the door fitted behind if possible.

Behind Opening Fit

If you are ordering to install behind the garage opening and have plenty of side and headroom you can simply calculate the door size you need by ordering the nearest standard size to your structural opening whether it be smaller or bigger - REMEMBER - The sectional door does not project forwards at any point during its operation so a sectional door larger than the opening fitting behind will still open perfectly OK.

A sectional door size smaller than the opening is also fine, up to a point as the vertical frame legs can be exposed as well as the steel header section and these can all be easily exposed up to 85mm all round before you have to consider it as an inbetween opening installation.

With behind opening installations you also can fit behind curved arches and all sorts of other odd shaped garage openings unlike many other door types.

Narrower doors may require frame cover profiles however to colour match the frame legs if you do not require white. The header section supplied with the door is alway s the same colour as the door panel chosen.

The headroom required as mentioned and shown earlier depends on the spring type ordered and this is as follows:

Z Tracks (single width door up to 3048mm wide generally) require 100mm headroom

L Tracks (Double doors ordered as a ‘low headroom’ option) require 100mm headroom

These measurements are all for manually operated doors and for the standard remote control electric operator systems from Hormann you simply have to allow another 25mm more as a minimum to allow for the operator boom section which is usually at least 3200mm in length and longer for doors ordered above 2125mm high.

For the XXL doors measurements will vary depending on the operator type used which is normally based on frequency of use and door size/weight.

Non standard metric doors (European range)

XXL Tracks (Double doors over 5500mm wide) require 390mm of headroom

XXL ‘low headroom’ (as XXL but with rear mounted springs) require 200mm of headroom

Inbetween Opening Fit

When ordering a Hormann sectional door to install inbetween a structural opening it usually means that you will be installing underneath the support lintel (RSJ) as well. In this case you will have to calculate the door size by taking 100mm off either side of the opening width (90mm plus 10mm tolerance) and the headroom required is dependant on the spring type for the door you are ordering. You can then either order the nearest standard size or have a door either cut to size from a standard or purpose made from the factory (Cut down sizes only available on double skinned doors – LPU40).

Whatever you choose to do you will need the inbetween installation kit to provide you with correct brackets to secure the frame legs and header to the structural opening.

The easiest installation for between an opening is the Z track type (side mounted springs) as this spring type only requires 100mm around the door order size and has no requirement for fixing points normally for a front mounted torsion spring as in the N tracks.

For installation between structural openings you will need a bracket kit (inbetwen fit kit) and if the door is not a standard white finish you will also need a set of frame cover profiles to cloak the standard frame legs as they are always white in colour.

For installation between structural openings you will need a bracket kit (inbetwen fit kit) and if the door is not a standard white finish you will also need a set of frame cover profiles to cloak the standard frame legs as they are always white in colour.You can have the cover profiles in different surface finishes too - silkgrain, woodgrain, decograin, etc and they are also available in 55mm or 90mm widths depending how much may be showing.

Important Note

The installation of the front mounted torsion spring for N track gear requires a minimum of one near central bracket fixing to support the spring system and more on larger doors (details available on request). This fixing is very important, so if you are installing underneath a steel or timber lintel you will have to find a suitable method of getting this bracket supported. This could either be a structural steel or timber section across the opening or a suitable steel or timber section dropping down in front of where the bracket is required in the opening. Once this fixing is achieved with the N track gear you then have to consider how to infill the open space created above the 90mm fascia supplied as the total headroom required is 210mm so you have 120mm left (210mm – 90mm).

Insulated fascia infills are available for the perfect solution from Hormann in matching materials to the door design and colour chosen but are not ‘off the shelf’ items and will generally be 4-6 weeks delivery, please email or call for details.

Other methods used include Upvc fascia boards on steel or timber supports or timber shiplap cladding on a timber framework system to name just 2.

Many accessories for finishing around the brickwork opening are available from Hormann to help make a replacement door look smart and well sealed, please call for latest details and pricing. Some examples are shown below:

A new fascia is now available for flush fitting of the top panel section! (ask for details) - This makes the entire door look as one continuous sectional door when closed.

The image below shows the principle of this insulated fascia section.

Dimensions shown below for the standard gear arrangements for a Hormann Sectional garage door.