The SeceuroDoor range of industrial and commercial roller shutter doors are the result of many years of development and redevelopment to create a wide range of doors with excellent reliability and total compliance with the very latest regulations for electric operated doors.

Single skin steel doors for more basic requirements and features and double skinned, insulated steel doors for higher performance and options for higher speed operation. On top of this there are SeceuroDoor security shutters with tested and certified burglar resistant features and certifications. The SeceuroDoor range covers around 90% of what most buildings would require from a rolling shutter door in the UK for an external door purpose.

How to choose the Right Door Model...

The entire range has been split by Samson Doors into prespecified roller door models and this is how you go through options and check which one is right for you.

1. Choose whether you want an insulated or non insulated roller door curtain.

The SeceuroDoor 75 doors are all single skin galvanised steel curtains and relatively basic in terms of their performance, although there are security rated models available. They have no insulation properties.

The SeceuroDoor 77, 95 and 100 are all double skinned steel curtain doors which not only offer insulation but are stronger and quieter in their operation. Because the door slats are heavier they sit down closed and generally won’t rattle in the wind but also offer greater overall strength.

They can be uprated with a high speed motor and this also means you can have a high usage motor rating for any door requiring to be opened many times a day, usually more than 20 times per hour. The higher speed versions of the 95 and 100 model will appeal to any building where the doors are used often but also left open a lot because the current door is too slow.

2. Choose single or three phase electric motor operation.

On most doors we are offering 3 types of motor drives.

The most basic is the single phase 240V tube motor, which is limited in number of operations per day and also limited in the door sizes. It is perfect for any opening which might be opened less than 12 times a day and isn’t too large.

The single phase electric motors, which are external mounted are the next stage up in terms of performance, offering more operations per day and also available as a chain operated or direct drive motor (see below) set up.

The three phase electric motors are the most powerful and used on larger doors, or where there is a need for high speed and/or hi usage doors.

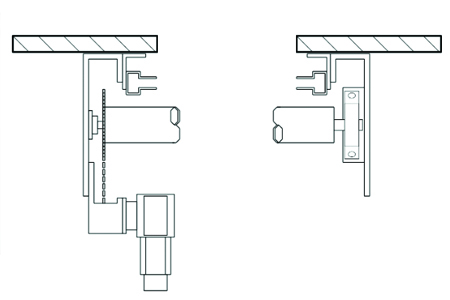

3. Chain or Direct Drive Motor Arrangement.

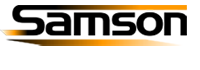

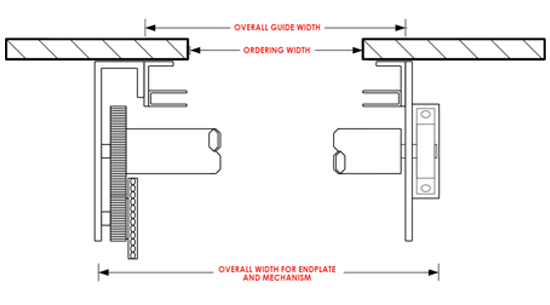

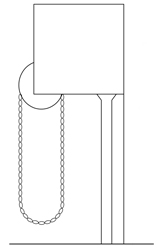

A lot of the industrial roller shutters have the option for either a chain driven motor or a direct drive motor. There is a difference in the installation space required for each motor - A direct drive motor is set as an ‘outboard’ motor and sits outside the endplate at one end of the shutter attached directly to the barrel and curtain of the door. The chain driven motor usually sits inboard within the endplates taking up more space internally but not requiring any space outside the endplates.

|

|

|

| Inset Inboard motor position | Inset Outboard motor position |

There is no real immediate saving on cost as the prices vary on many other factors but many people will ask which one is best and in reality this is always the direct drive motor. The simple fact is a Direct Drive motor has less moving parts, no coupling, chain, gearbox, etc and the direct drive puts the power from the motor directly onto the load of the roller door barrel and curtain. A direct drive motor is the only option when you require a hi speed or hi usage roller door model from our range.

A major factor in the choice quite often is based on the installation space available but if you have enough space and want a recommendation, then always go for a direct drive motor.

The 240V Tube motors are built inside the curtain barrel and are always the same in terms of their performance and relevance. They are for small to medium size doors with low usage.

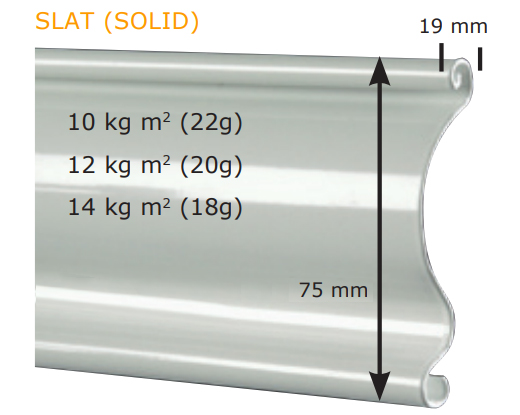

4. The Steel Curtain Thickness - 22 guage or 20 guage?

We have split the door models further down to options with the actual thickness of the single skin lath sections on the SeceuroDoor 75 models. Hopefully this is a relatively obvious difference in that the 22 guage curtain is thinner steel than the 20 guage models and we also offer 18 gauge models if required too.

Thicker steel curtain will equal more strength and more weight but also gives some larger size options which can be seen in the height limits for some models.

20 gauge steel curtains will be slightly more money than the 22 guage but offer a stronger curtain overall.

Now you have hopefully narrowed down to a specific door model or 2 you can start to specify and price up…

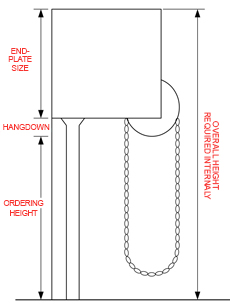

1. Choose the Width and Height for the Ordering Size and Price

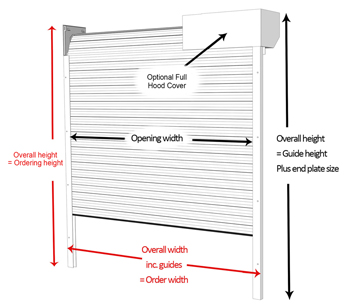

We have built the industrial ‘Traditional’ roller doors in our online shop to be ordered by the ‘Daylight Opening Sizes’ which generally means the width between the side guides and the height to the top of the side guides, leaving out the dimensions for the guides either side and the endplate at the top housing the barrel and curtain and motor.

The ‘Continental’ build doors are ordered differently and use the Overall Width and Overall Height to include the side guides and the endplate and hood cover.

The main reason for this stems from most traditional industrial doors being fitted internally to the face of an opening inside. The Continental build doors are primarily used for inbetween opening fit but can also be fitted behind or even to the outside face externally.

2. Choose the Side for the Electric Motor Drive

Looking from inside the building outwards you choose which side you would like the motor drive and this is also the side generally for the power and controls to be situated, including the manual emergency override which is taken off the motor drive.

3. Choose the Guides and Fitting Arrangement

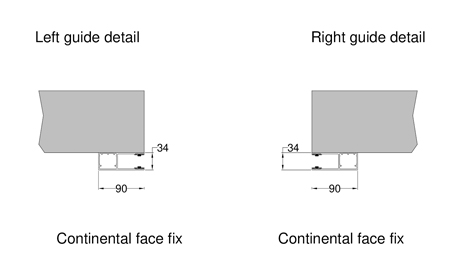

A Continental set up will always give you the same and only option with generally 90mm one piece aluminium guides set in line with the endplate at the top. This set up is great for any inbetween aperture installations.

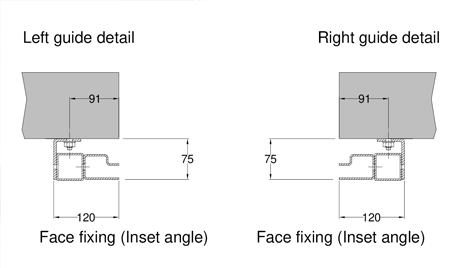

For the Traditional industrial roller doors you have a choice of how the side guides and angles are set up for installation which will depend on your steelwork, brickwork or blockwork on the aperture and getting the fixings in the best position.

The motor side will often require more side room than the non motor side, but we will always provide a drawing for approval before manufacturing proceeds so you can double check everything is correct.

Always remember whatever dimensions/drawings you are looking at the endplates and motor at the top of the roller shutter will inevitably require more side room than the guides require.

Continental Set Up |

|

4. Endplate and Roll Fitting Position

We simply ask if the roller shutter curtain is to be fitted on the inside face along with the guides or to be fitted underneath any lintel as a ‘reveal’ fit.

If you are fitting the roller door underneath a lintel then you will need a hood cover unless you are creating a fascia already. The door curtain will be visible and exposed from the outside obviously if you install underneath a lintel and don't have a hood cover or fascia in place.

5. Door Curtain Colour

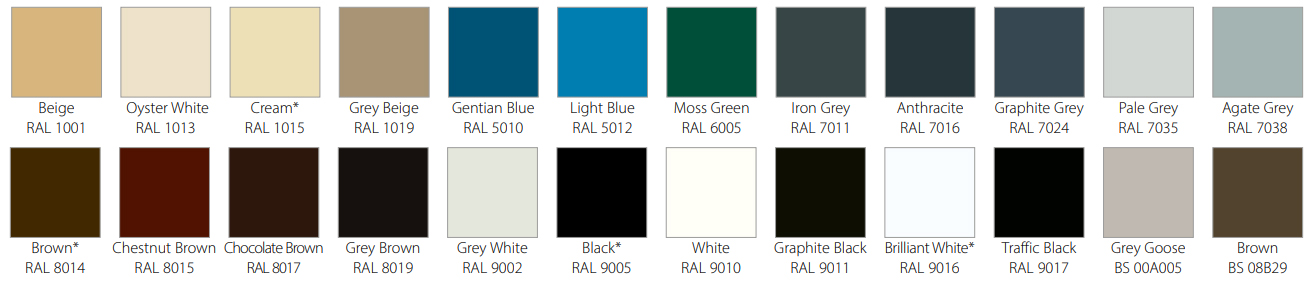

Choose between the various colours offered, but also be aware on many door curtains, depending on their specification, we offer either a plastisol or powdercoat finish option for the external face. Prices will vary depending on the finish and colour chosen.

6. Bottom Rail Selection

The bottom of any roller shutter door often has options on the type of rail fitted and when you are looking at auto closing or remote control options then you will need a safety edge system included.

For a manual or simple ‘hold to run’ control system, then a standard T rail is sufficient.

This T rail principal is the same, whether the door is single or double skinned as a curtain.

7. Door Control Method

For a manual door of course you don't have this option because you are using a chin pulley system without a motor, or a spring assisted push up and pull down system.

We have many varied options if you wish to do more complex controls on any of the roller shutter doors. Auto opening from radar detectors, timers, etc and integrated controls with other systems are all possible. On our door range the 3 options we offer will cover 90% of customers requirements usually and we have the control panel and accessories married to the motor perfectly for the most reliable overall results. We only use GFA motors and controls as standard generally and these are one of the only manufacturers offering an extended 2 year warranty on their commercial motors.

Control package 1 provides a simple wall mounted push button control with a ‘hold to run’ or ‘deadman’ control principle with minimal electrical components required and no safety edge required in most cases as long as the control panel is in direct line of sight of the door it is controlling at all times

Control Package 2 provides a similar wall mounted control panel but with the added advantage of auto closing included. This means you can push as an impulse only the buttons and walk away whilst the door completes its opening or closing cycle. This does require a safety edge system which is included with the control.

Control Package 2 provides a similar wall mounted control panel but with the added advantage of auto closing included. This means you can push as an impulse only the buttons and walk away whilst the door completes its opening or closing cycle. This does require a safety edge system which is included with the control.

Control package 3 provides the same as 2, but with 2 hand held remote controls for additional control of the door. More handsets can be purchased and the door includes the safety edge detection. We would recommend the addition of an infra red beam for this type of control and this is down to a site assessment. If the door is adjacent to any public road or pathway then it would be advised to be installed for additional safety.

Control package 3 provides the same as 2, but with 2 hand held remote controls for additional control of the door. More handsets can be purchased and the door includes the safety edge detection. We would recommend the addition of an infra red beam for this type of control and this is down to a site assessment. If the door is adjacent to any public road or pathway then it would be advised to be installed for additional safety.

Special - POA This can be almost any controls but will need a proper discussion and analysis with our sales team.

8. Control Accessories

For some simple extra controls for your door we have provided some options here.

External keyswitches or digital keypads when you have safety edge fitted.

For anything not listed please email or call us for prices and details.